Thickness Gauge LC-160

- Wear-resistant probewith ruby tip

- Support Bluetooth and mobile APP

- Iron galvanized identification(LC-160 blue backlight prompt)

- Iron powder putty identification(LC-160 red backlight alarm)

- Response time is less than 0.5 seconds

- Accuracy ±(2%reading+1μm) (0~2000μm)

- Range 0~3000μm

Description

LC series automotive paint meter can non-destructively measure the thickness of non-conductive coatings on metal surfaces, as well as non-ferromagnetic metal coatings on ferromagnetic metals (such as iron, nickel and cobalt, etc.), specific applications include measuring iron, stainless steel surface paint or galvanizing layer thickness, measure the thickness of aluminum, copper surface paint or plastic film, etc.

LC-160 has a built-in magnetic induction and eddy current effect probe, with a measurement range of 0~3000μm, of which the measuring accuracy of 0~2000μm is ± (2% reading+1μm).

LC-160 is only with one button, the operation is very simple. During measurement, the user only needs to quickly attach the probe end to the surface of the object to be measured. During the process of shrinking the probe to the inside of the instrument, the instrument can automatically distinguish the properties of the substrate and measure the thickness of the coating (plating) layer. The measurement results can be sent to the mobile APP in real time by Bluetooth. In addition, the instrument contains a large memory capacity. During the measurement process, the instrument automatically counts and records the measurement results. The recorded data can be transferred to a computer via a USB cable.

LC-160 is suitable for car paint inspection: While measuring paint thickness, it can also identify iron galvanized and iron powder putty materials. The instrument has strong anti-interference ability and can work normally in a more complex electromagnetic field environment.

FEATURES:

- Wear-resistant probewith ruby tip

- Support Bluetooth and mobile APP

- Support USB data transfer

- Support USB to upgrade instrument firmware

- Iron galvanized identification(LC-160 blue backlight prompt)

- Iron powder putty identification(LC-160 red backlight alarm)

- Response time is less than 0.5 seconds

- Accuracy ±(2%reading+1μm) (0~2000μm)

- Range 0~3000μm

- Single buttonoperation

- Zero calibration

- Condensed menu

- Display maximum, minimum, average and numbers of measurements

- 10 measured valuescan be checked back

- Automatic shut-down

- Battery protection

Datasheet

|

Model |

LC-160 |

|

Measurement Principle |

Fe: Magnetic induction; NFe: Eddy current effect |

|

Measurement Range |

0~3000μm |

|

Accuracy |

±(2% reading+1μm), ≤2000μm ±(3% reading+2μm), 2001~3000μm |

|

Resolution |

0.1μm (0~99.9μm); 1μm (≥100μm) |

|

Unit |

μm, mm, mil |

|

Iron Powder Putty Identification Range |

0~2000μm |

|

Iron Galvanized Identification Range |

3~1000μm |

|

User Calibration Method |

Zero calibration |

|

Probe Trigger Force |

0.5~1.2N |

|

Minimum Radius of Curvature of Substrate |

Convex 5mm Concave 25mm |

|

Minimum Measurement Area |

Diameter 15mm |

|

Minimum Substrate Thickness |

Fe: 0.20mm; NFe: 0.03mm |

|

Reaction Time |

< 0.5 seconds |

|

Display |

Dot matrix LCD screen |

|

USB Data Transfer |

Support |

|

Bluetooth & APP |

Support |

|

Operating Temperature |

-10~+50℃ |

|

Stored Temperature |

-20~+60℃ |

|

Power Supply |

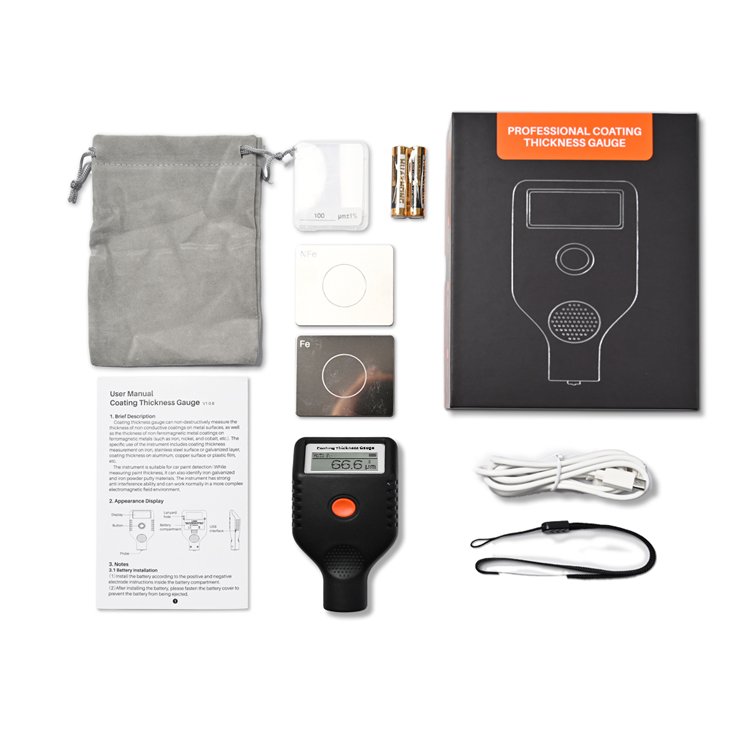

2pcs 1.5V AAA alkaline batteries |

|

Protection Class |

IP40 |

|

Dimensions |

103*62*27mm |

|

Shell Material |

ABS |

|

Weight |

About 60g (without battery) |

Video

Coming Soon!

User Manual

FAQ

1-Can I customized with own logo?

Quick Compare

Parametric filtering: From specs to selection.